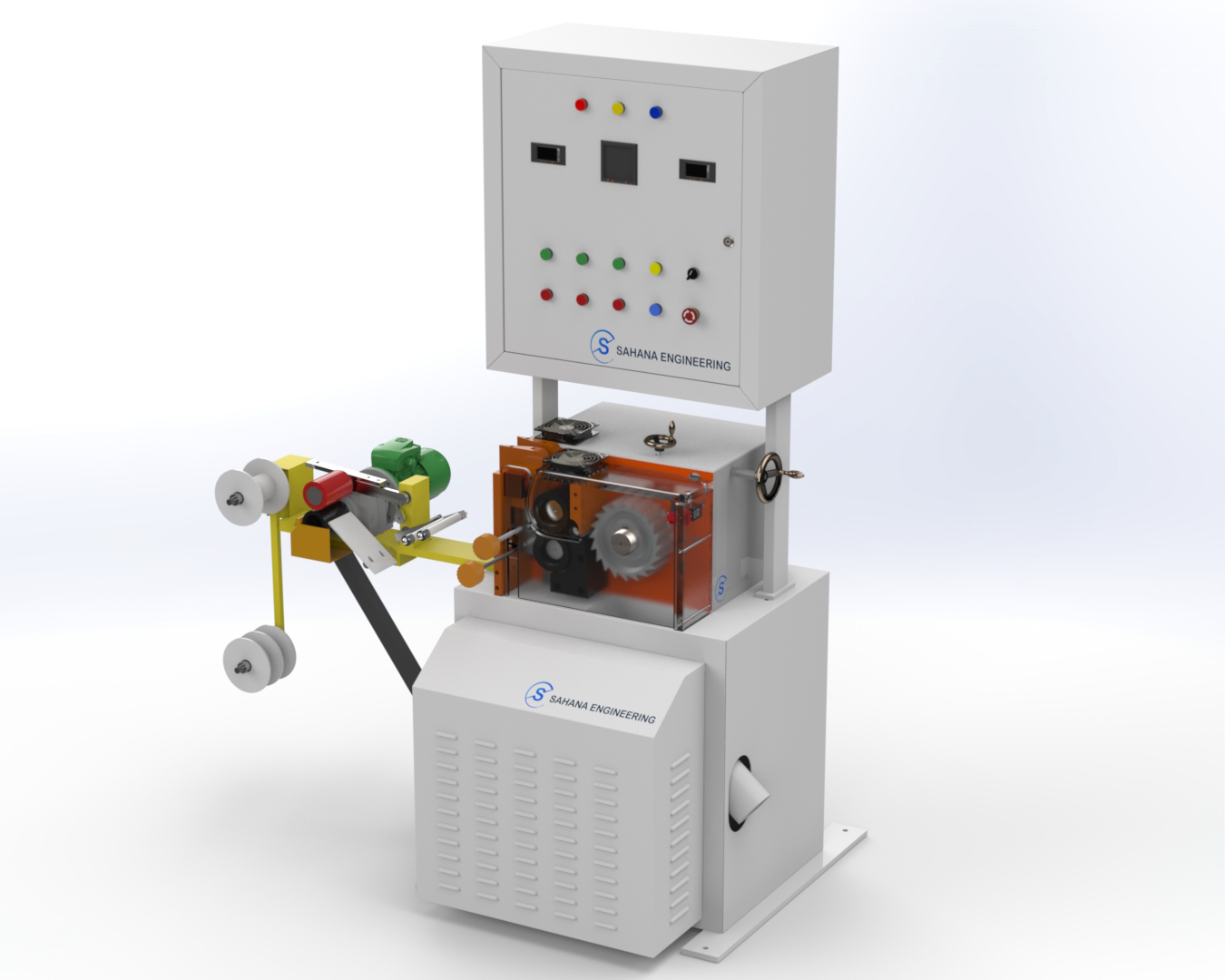

In today’s manufacturing world, factory owners and decision-makers are constantly seeking efficient and sustainable solutions for managing waste materials. One crucial step is selecting the right RG machine to recycle EVA foam strips—an essential component of many products including footwear, sports mats, packaging, and more. A reliable recycling process can reduce waste, lower production costs, and improve your company’s environmental impact.At Sahana Engineering, we help businesses in recycling EVA foam strips into granules making smarter, more sustainable equipment choices.

If you’re in the market for a new RG machine for your facility, here are 7 expert tips to guide your decision.

1. Understand Your Material Type

EVA (Ethylene-Vinyl Acetate) foam comes in various densities and forms—such as sheets, rolls, or strips. Not all machines are designed to handle every variation. Ensure the RG machine you choose is optimized for recycling EVA foam strips, as this will reduce wear on the machine and improve output quality.

2. Check the Grinding Capacity

Grinding capacity is one of the most important specifications to look at. How much EVA foam can the machine process per hour? If you’re recycling large volumes daily, you’ll need a heavy-duty machine with high throughput. Always ask the manufacturer for case studies or real-life examples based on similar use cases.

3. Look for Dust Control Features

Grinding EVA foam can create a lot of fine dust. Machines with integrated dust extraction or collection systems will help maintain a clean work environment and protect your workers’ health. This is especially important if you’re operating in a closed or indoor factory setting.

4. Assess Blade Quality and Maintenance

A good RG machine should have durable, sharp, and easily replaceable blades. EVA foam can dull blades over time, so check whether the machine offers easy blade maintenance or auto-sharpening features. This reduces downtime and ensures consistent grinding quality.

5. Energy Efficiency

Energy consumption directly affects your monthly operational costs. Choose an RG machine with energy-efficient motors or features like auto shut-off when idle. Over time, this can result in significant savings for your facility.

6. Warranty and After-Sales Support

Machines dealing with materials like EVA foam strips need occasional maintenance. Always check what kind of warranty the manufacturer offers and how responsive their support team is. Do they provide remote diagnostics or on-site repair service? These factors can save you from long downtimes in the future.

7. Customization Options

Every factory has different layouts, power capacities, and recycling goals. Some manufacturers offer custom-built RG machines tailored to your needs. Whether it’s output size, feeding method, or even color coding for safety—consider asking for a customized solution.

Why Recycling EVA Foam Strips Matters

EVA waste is non-biodegradable and can take centuries to break down. By investing in a powerful RG machine, your business not only reduces its carbon footprint but also creates opportunities to reuse ground material in new product lines. Recycled EVA foam can be used in padding, mats, insulation, and various other products.

Final Thoughts

Choosing the right RG machine is more than a purchase—it’s a long-term investment in your factory’s productivity, cost efficiency, and environmental responsibility. Evaluate the factors above carefully, and don’t hesitate to consult with machine manufacturers before making a decision.

By choosing the right equipment for recycling EVA foam strips, you ensure consistent production, reduced material waste, and a greener footprint for your business.

Contact Sahana Engineering

At Sahana Engineering, we deliver custom-built RG machines that are efficient, durable, and optimized for your unique production needs. Whether you’re recycling EVA foam strips, blocks, or composite material, we’ve got the solution for you.